Why do customers always say it's too expensive to buy titanium bars?

In the past titanium metal sales,we often met the customer told me :your price is too expensive!yo should give me some discount.Actually,first Don't talk to the customer about price, talk more about value. Don't be afraid that the customer say price is too expensive.

How to solve this problem? Now value principle comes in.

Many salesmen for titanium rod complain that no matter how low the price is quoted, the customer thinks it is too expensive. Such an objection is not strictly a rejection. We should analyze the different reasons why the customer thinks it is expensive.

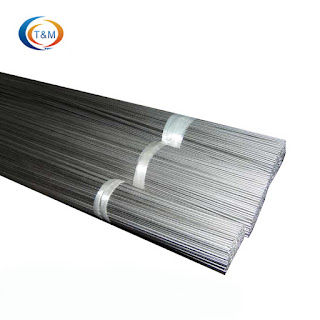

First of all, i think let the customer know the process flow is important:you may have an expert customer who knows the rare materials price for titanium sponge or even scrap titanium ingot .so they can calculate the finished price .it is good ,but i think you still need to let the customer know the process flow for titanium rod.because some application need two melting,and some need three times meltings,it different cost.and for titanium metal forging,If the forging time is enough, the grain structure will be broken evenly, and the performance will be better. Of course, the higher processing time determines the higher price.

Different scale of the factory have different production cost, but it is important to note : 1.large-scale factory has plenty of titanium ingot material support, compared with the small factory, he can control the overall consistency of raw materials, rather than a small factory with the batch of raw material may come from different manufacturers, so how to ensure consistency with the batch of product performance. In addition, the big factory has a perfect processing control , and the processing records of each step are well documented, so that any problems in the future can be solved in the first time. However, the small factory has no production records for the first processing, which is very terrible for customers who pay attention to product quality.

2. the inspection link, the large-scale factory will with more than five inspection personnel quality inspection departments, including surface testing, performance testing, etc., but the problem of small factory is produced products supply direct to customers, take customer as the terminal inspection:

3. After-sales service: whether it's transport problems or other quality disputes, big factory can give customers the the solution of returned goods or exchange in the first time, but small factory consider cost issues, will be poor responsiveness.

So customer may be considered that the cost is slightly lower when purchasing, but if the purchased titanium rod cannot be used, no matter it is re-purchased from another manufacturer or asking for a refund, the time cost and remittance loss are all intangible risks.

We strive to be a honest supplier in the titanium metal market,no matter for titanium rod,but also titanium plate,titanium wire and titanium tube,we will try to know the real use for this items,then choose the proper materials for customer.we need to get both win .

We know for customer he do not worry about high price,but only worried they pay high price but received a bad goods,so chatting for more for more details will help you find the best resource for titanium metal materials.

评论

发表评论