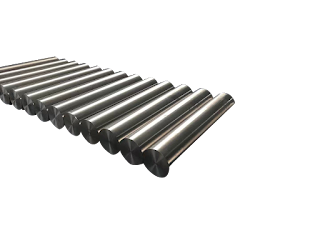

Titanium alloy Gr.5 titanium block wholesale

Titanium alloy gr5 titanium block wholesales.

We are the professional manufacture for titanium forging.not only pure titanim block,but also titanium alloy block,and we know how to control the best property for titanium forgings,today we would like to share you some details for titanium alloy foring .

1. Segregation type defect

In addition to beta segregation, beta spots, titanium-rich segregation and bar alpha segregation, the most dangerous is gap type alpha stable segregation (I type alpha segregation), which is often accompanied by small holes, cracks, containing oxygen, nitrogen and other gases, brittleness. There are also aluminium-rich alpha stable segregation (type II alpha segregation), which also present dangerous defects with cracks and brittleness.

2.Most inclusions are metal inclusions with high melting point and density. High melting point, high density by titanium alloy composition elements not fully melted in matrix form (such as molybdenum inclusions), there are mixed in the smelting of raw materials (especially the recycled material) chip carbide cutting tools collapse or improper electrode welding process commonly used (titanium alloy smelting vacuum consumable electrode remelting process), such as tungsten arc welding, the high density inclusions, such as tungsten inclusions, and titanium compound inclusions, etc. The presence of inclusions can easily lead to the occurrence and expansion of cracks, so it is not allowed to exist defects (for example, the Soviet union stipulated in 1977 that high-density inclusions with diameters of 0.3~0.5mm found in X-ray examination of titanium alloy must be recorded).

3.Residual shrinkage cavity

4. Defect Holes.

The existence of holes may not be single, but may be multiple and dense, which may accelerate the growth rate of low-cycle fatigue crack and lead to premature fatigue failure.

5.Crack .

Mainly refers to forging crack. Titanium big viscosity, liquidity is poor, and thermal conductivity is not good, therefore in the process of forging deformation, high 5.Crack .

Mainly refers to forging crack. Titanium big viscosity, liquidity is poor, and thermal conductivity is not good, therefore in the process of forging deformation, high friction on the surface, the internal deformation inhomogeneity and inside and outside temperature difference obviously, easier to produce in forging internal shear zone (strain), serious when that lead to crack, its orientation along the direction of the maximum deformation stress.

6.Overheating .

Titanium alloy thermal conductivity is poor, in the process of thermal processing in addition to improper heating caused by the forging or raw material overheating, in the process of forging is also easy because of the thermal effect of deformation caused by overheating, causing changes in microstructure, the formation of overheating wei's organization.

We are the professional manufacture for titanium forging.not only pure titanim block,but also titanium alloy block,and we know how to control the best property for titanium forgings,today we would like to share you some details for titanium alloy foring .

1. Segregation type defect

In addition to beta segregation, beta spots, titanium-rich segregation and bar alpha segregation, the most dangerous is gap type alpha stable segregation (I type alpha segregation), which is often accompanied by small holes, cracks, containing oxygen, nitrogen and other gases, brittleness. There are also aluminium-rich alpha stable segregation (type II alpha segregation), which also present dangerous defects with cracks and brittleness.

2.Most inclusions are metal inclusions with high melting point and density. High melting point, high density by titanium alloy composition elements not fully melted in matrix form (such as molybdenum inclusions), there are mixed in the smelting of raw materials (especially the recycled material) chip carbide cutting tools collapse or improper electrode welding process commonly used (titanium alloy smelting vacuum consumable electrode remelting process), such as tungsten arc welding, the high density inclusions, such as tungsten inclusions, and titanium compound inclusions, etc. The presence of inclusions can easily lead to the occurrence and expansion of cracks, so it is not allowed to exist defects (for example, the Soviet union stipulated in 1977 that high-density inclusions with diameters of 0.3~0.5mm found in X-ray examination of titanium alloy must be recorded).

3.Residual shrinkage cavity

4. Defect Holes.

The existence of holes may not be single, but may be multiple and dense, which may accelerate the growth rate of low-cycle fatigue crack and lead to premature fatigue failure.

5.Crack .

Mainly refers to forging crack. Titanium big viscosity, liquidity is poor, and thermal conductivity is not good, therefore in the process of forging deformation, high 5.Crack .

Mainly refers to forging crack. Titanium big viscosity, liquidity is poor, and thermal conductivity is not good, therefore in the process of forging deformation, high friction on the surface, the internal deformation inhomogeneity and inside and outside temperature difference obviously, easier to produce in forging internal shear zone (strain), serious when that lead to crack, its orientation along the direction of the maximum deformation stress.

6.Overheating .

Titanium alloy thermal conductivity is poor, in the process of thermal processing in addition to improper heating caused by the forging or raw material overheating, in the process of forging is also easy because of the thermal effect of deformation caused by overheating, causing changes in microstructure, the formation of overheating wei's organization.

评论

发表评论